Gus Green of Launceston recently got in touch to share with us the success of his latest project, a revamp of his deck.

“That is using a recycled composite board 190mm wide 23mm thick as a new surface over the top of tiles, using Techniglue to glue Aluminium strips as battens to the cement tiles then using ATL’s Techniglue R60 to attach the composite re-cycled decking to the Aluminium battens without screws for this process,” as Gus explains.

Techniglue R60 is a high strength adhesive perfect for this application and for bonding structural elements in a wide range of applications. It is commonly used in civil construction for mechanical fastenings and laminated beams. , and has approval for VOC compliance under the specification of the Green Building Council of Australia / Green Star Office Design V3 IEQ-13.

https://atlcomposites.com.au/category/1/Adhesives

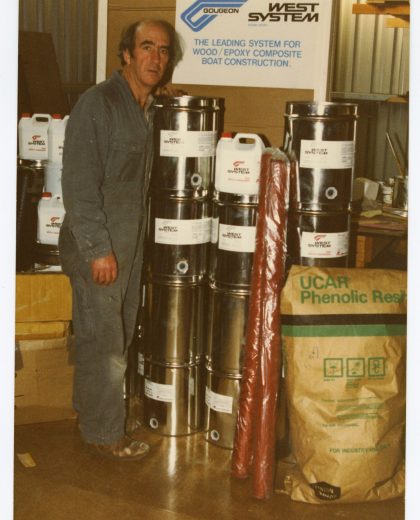

Looking back, Gus was the first WEST SYSTEM epoxy distributor in Australia, who in 1978 air freighted the products over in tin containers.

The relationship began with a reconnaissance trip to New Zealand. “We wanted to start building boats,” he says. “And so I flew over to New Zealand to look at woodwork machinery.”

During the flight, Gus read a copy of Seaspray NZ magazine and an article on the Bonito 22 caught his eye.

“When I landed, I phoned Bonito Craft and they took me for a sail that day on Auckland Harbour. From there, I imported 17 yachts from them. I also wanted to visit WEST SYSTEM’S Chris Timms, who was manufacturing the WEST SYSTEM products under licence to Gougeon Brothers Inc in the USA.

“I ordered a range of products which was air-freighted to Launceston. We built a couple of boats like that, namely Young 10s, another NZ design.

Duthie Lidgard managed the second WEST SYSTEM facility in Sydney in 1980, Adhesive Technologies, which later became ATL Composites in 1989, to service the Australian professional and amateur boatbuilding market.

Gus, who describes his career as “an independent agent, building and selling boats, staking on odd jobs, supplying boat builders and furniture making”, said he has seen the development of WEST SYSTEM under the direction of ATL Composites since the 1980s.

“Lorraine and I have known each other for many, many years. It’s a wonderful product range – the most adaptable range of products you could ever use and wonderful for persuading people beyond the boating industry to use a resin over what they’ve been using for umpteen years. The results speak for themselves.”

As Gus recounts, “Boat builder Ian Milner at 9A Murphy Street built a half-size replica of Tony Bullimore’s boat using WEST SYSTEM epoxy for the film ‘Miracle at Sea: The Rescue of Tony Bullimore’. There’s no end to the applications!

“I can also see a great future for the WEST SYSTEM 207 Special Clear hardener. I used some the other day. It’s absolutely perfect for repairing statues in the garden. There are so many uses. You could make your own pebble stepping stones.”

When mixed with WEST SYSTEM 105 Resin, WEST SYSTEM 207 Special Clear has been specifically formulated for coating and to resist clouding in humid conditions. It has strong physical properties so it can also be used as a structural adhesive for gluing and laminating, and provides a beautiful long-lasting finish when used with a quality UV-filtering varnish.

The indefatigable Gus is now semi-retired but still creative and productive.

“It’s interesting to reflect on my great unplanned adventure with WEST SYSTEM, all from a small ad in a magazine on an aircraft. It was an interesting beginning to a life-long relationship.”