Composites and creativity were the magic ingredients behind the scenes at Movie World for its annual White Christmas celebrations.

The White Christmas street parades were bigger and brighter than ever this year, thanks to the life-like replica landmarks created by Sculpt Studios using composite products from ATL Composites.

With the theme of “Joy to the World”, the nightly parades, led by Santa Claus on his sleigh, involved motorised floats with landmarks from London, Paris, New York, Rome and Sydney, as well as beloved characters such as Gizmo from Gremlins, Bugs Bunny and Tweety, flanked by dancers and characters in costume.

The Sculpt Studios team comprises prop set specialists, sculptors, including Director and founder, Liam Hardy – notable for his bronze statues of sporting legends Mal Meninga, Arthur Beetson, Allan ‘Alfie’ Langer, John Eales, Laura Geitz, and work on film sets, various hotel projects and international theme park projects.

Robbie McGaw, General Manager at Sculpt Studios, says that while it’s a massive annual undertaking, their team is well-equipped to deliver the impressive displays.

The Sculpt Studios artists and craftspeople have many years’ experience creating sets and special effects for movies.

“It takes the same skills, the difference is guest interaction,” Robbie explains.

“For Movie World and other clients, these are not just props, they’re permanent. They have to take wear and tear, weather in some cases, and last for 20 years or more, so it has to be bullet proof.”

Robbie has a background of 17 years’ chandelier making for Westfield and AMP shopping centres, including the extraordinary illumination and decoration at Pacific Fair.

“Our job is devising creative solutions that are outside of the box. Our custom fabrication projects need to keep the public and their safety in mind without complicating the engineering.

“We specialise in impossible projects that we engineer and fabricate, using composites and concreting, Glassfibre Reinforced Gypsum (GRG) and Glassfibre Reinforced Concrete (GRC). We also work on custom construction projects using our 3D CNC machines to create plaster work on large homes, hotels and commercial properties.

“For example, we were commissioned by GCB Constructions to produce the 3D design and digitally fabricate the domes of the two ‘pods’ for a luxury home at Point Danger. We’ve undertaken several projects in Dubai and Doha, and for the World Cup in Qatar, and for the Microsoft Head office in Sydney, which has sculptural rock walls.”

At Sydney’s Taronga Zoo, Sculpt Studios were called on to create realistic sprayed-concrete rock walls for the Savannah enclosure and the Nocturnal House, along with the design and construction of three sculpted environmental rooms for the Taronga Institute of Science and Learning.

For White Christmas at Movie World, Sculpt Studios had three months from finalising the design to the start of the parades to create the life-like scenes fitted around vans that would dazzle and delight thousands of visitors to the theme park during December.

“The team at Movie World develops concept drawings, usually pencil sketches or renders, and we take it from there. We fabricate them from scratch at our facility in Molendinar.”

To create the Eiffel Tower miniature for the Paris float, they used 3D models, then scaled it to cut the structural shapes to make it 6-metres in height. The tower was made using 6mm aluminium which was cut using waterjet then powder coated and the theming around it was custom made using marine-grade plywood upon which they modelled the scenery.

“We take the design, make a miniature in clay, 1:10 ratio, and then use a 3D scanner to make sure it fits before 5 axis cutting the pieces in foam and then fibreglassing casting it.”

Like the Eiffel Tower, the Statue of Liberty in the NYC scene required ATL’s WEST SYSTEM products, because it can be used directly onto foam and doesn’t eat into it.

To complicate matters this year, the Sculpt Studios team was committed to delivering the massive structures for the new Leviathan attraction at Sea World.

“We worked around the clock, 60-hour weeks for six months,” Robbie recounts. “We had the Leviathan, Covid and White Christmas to handle, all at once.”

At Sea World, the Leviathan ride is a 32m high, 909m long wooden rollercoaster that’s part of The New Atlantis precinct – a $50 million addition that’s home to the Leviathan, Trident and Vortex rides.

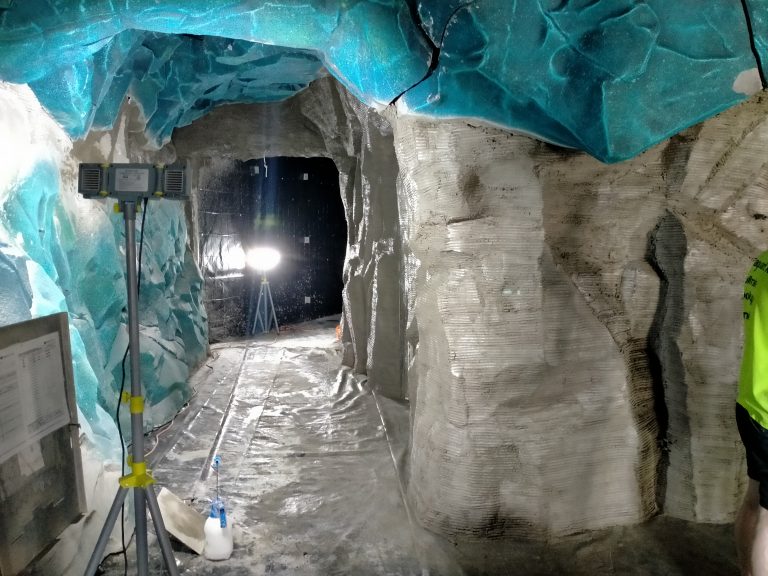

The external theming includes the entrance rockwork, 9m tall statues and cave system, which required 22 crew members working long hours to complete the project in time for the summer school holidays.

“It was the biggest project we’ve had since Covid, and working on both at the same time was a real challenge. Our team are all locals and we brought on five extra scenic painters to get the job done on schedule.”

They used GRG for the entire hanging ceiling in rock – over 200-square-metres. The ceilings went in first, then technicians installed the screens in the roof for the audio-visual part of the experience, and finally, the Sculpt Studios team built the rock walls up around it.

The spectacular experience has been hailed “without a doubt the best-produced ride show currently in Australia” by the theme park reviewers at Parkz.com.au.

“Village Roadshow is our biggest customer,” says Robbie.

“We’ve done every major attraction for VRTP in the past 10 years, including the Batmobile, which is a JL52 street-legal, one of, V8 car we created using composites, fibreglass, plug then full mould. We were commissioned for a second one for Warner Bros Spain which was a shell over the top of a Toyota 86, complete with giant sub-woofer and speakers for effects.”

“We use a lot of WEST SYSTEM, drums of it, for concrete moulds. It’s reliable and easy to work with.”

For over 50 years WEST SYSTEM epoxy has been used to reliably build and repair boats, but its practical uses are not limited to boats or the marine industry, and it has been used in many exciting and innovative projects worldwide.

The versatility that makes WEST SYSTEM a valuable tool to boat builders also make it a valuable resource for fabricators in a wide range of other fields.